Case Study

Web Inspection

Overview

“The ultimate solution required the development of a bespoke algorithm that needed the really specialised expertise that Olmec had to offer. The innovative design was backed up by a thorough testing regime to prove that the system could meet our specification.”

Alan Jones

Manager UCE

In Short:

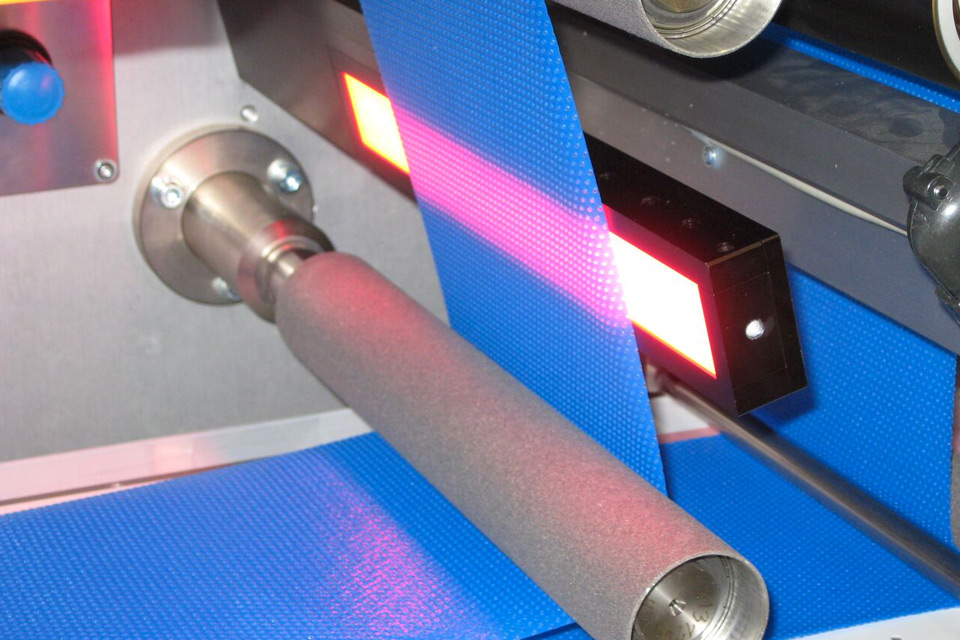

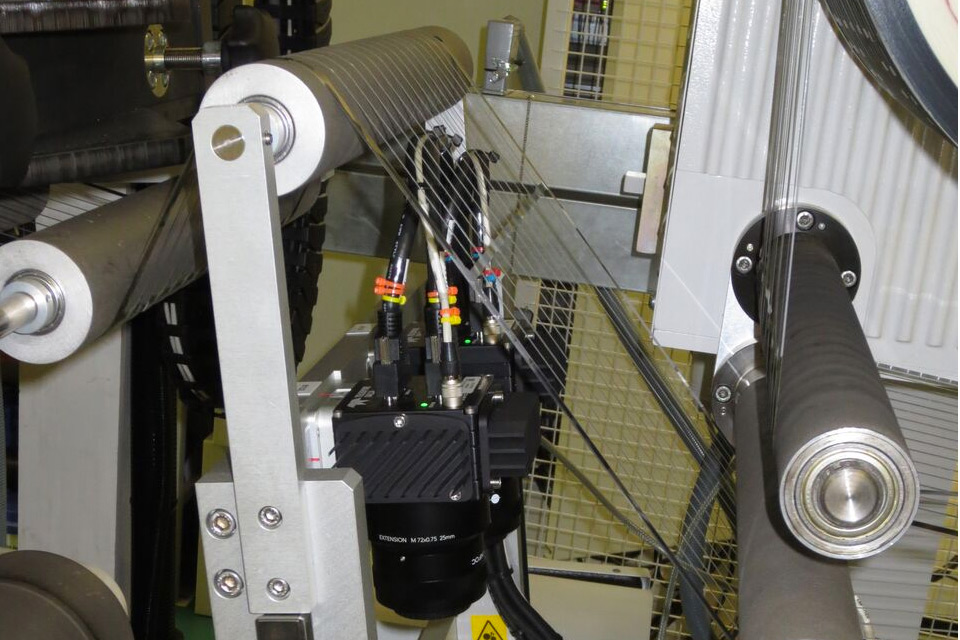

Web mounted in-line vision systems, providing 100% surface inspection of materials.

The Challenge

Nonwoven fabrics, films and plastics are produced in continuous rolls at very high speed so manual inspection is both costly and unreliable. Defects such as cracks, tears, holes and colour variation are difficult to detect and are historically found only at the end of a production run, which naturally has huge implications for manufacturing efficiencies.

Our Solution

Web mounted in-line vision systems, providing 100% surface inspection of materials including nonwovens, films and plastics. This continuous inspection allows manufacturers to identify and resolve problems early in the manufacturing process and ensure defective product does not reach the customer. Olmec web inspections, whilst also meeting any specific industry regulations, provide continuous real time monitoring and data logging offering the end user the benefit of full traceability for all material.

Where to next?

Olmec have delivered numerous web mounted vision systems which inspect the quality and consistency of the small holes integral to Modified Atmosphere Packaging (MAP). Further developments of the solution are now offered by our partner Rofin Baasel as VisionPerfoControl. We have subsequently applied the technology to microwaveable packaging to check that the laser micro-perforated holes that form part of a self-venting ‘steam valve’ system are present and complete.

![reckitt_benckiser_-_logo [Converted]-01.png](https://images.squarespace-cdn.com/content/v1/56c1fe8bc6fc08ef54840f7e/1456519964322-DJDNGVGVLHA3V8C6G75D/reckitt_benckiser_-_logo+%5BConverted%5D-01.png)